Part I: October 2016

Over a year and a half after first doing a test area on this aircraft, Aviana returned in October of 2016 to start the restoration on this T-33 fighter jet positioned outside of the Veterans Memorial Stadium in Cedar Rapids, Iowa. The plan was to finish it all in one week, but several obstacles prevented this goal.

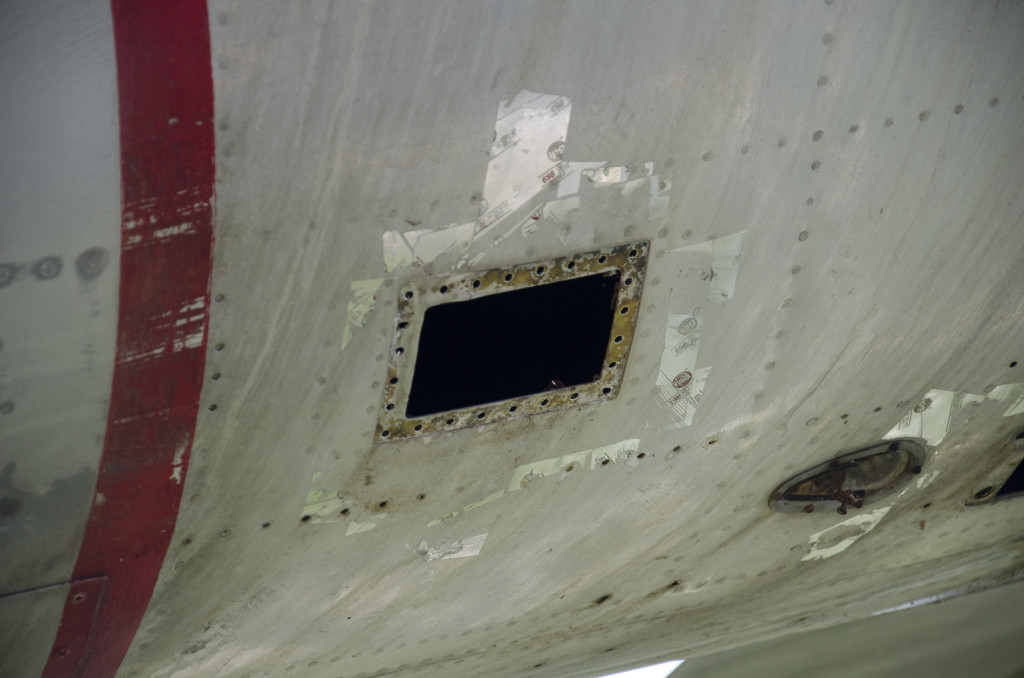

The first task, which was scheduled to take half of the first day, was to remove the steel plug in the exhaust, other patches, and access panels to allow for a more thorough cleaning by the Squeegee Squad. After drilling a hole and sticking a camera in, it became evident that the thick steel was holding back a large volume of animal excrement and carcasses. Oh joy!

Although most patches came off with ease, leaving just a tenuous mess of tape residue, the exhaust cover proved to be particularly challenging in removal, taking up a large portion of the first day.

After an early start on day 2 sanding the tail section, the boom lift we were using suffered a catastrophic hydraulic pump failure, rending it completely useless, and immobile! Fortunately, Squeegee Squad came prepared with an assortment of pressure washer extensions being able to reach deep inside the plane and wash out much of the animal refuse.

Much of the day was spent working to get a replacement lift lined up. United Rental’s service in this area was exceptional, but that didn’t change the fact there was simply nothing available at the time.

Sanding continued using an elaborate set of elevation adjusters. Take note of the defective lift in the background.

A glorious new lift was delivered by the guys at United Rentals! They upgraded us to one with a longer reach so that we could reach over the old one, which still immobile, was waiting for new parts to be shipped in and then would have to undergo field surgery.

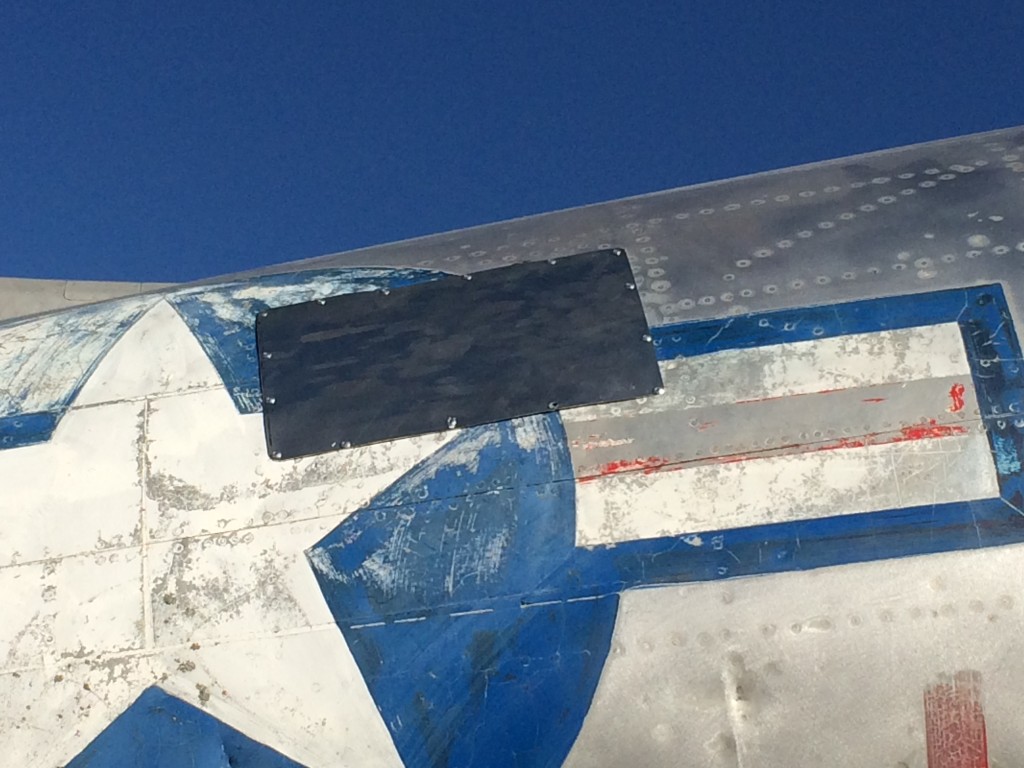

Jerod and Kevin Lynch, of Midwest Duck Blinds, also joined on day 3 and set their aluminum working experience to create patches for many of the missing or damaged areas on the jet. They hand traced, cut, and installed whatever they could reach!

Not only will this help with keeping animals out, once the aircraft is consistent in its finish, it will also conceal the damage incurred over the years.

Some actual polishing also occurred on this day! Note the old lift still in the way.

Much of the rest of the time was spent sanding and polishing. The process is very messy so not a lot of pictures were taken.

Tape residue had to be removed prior to any sanding. This took far longer than expected.

After removing the residue, aircraft markings were observed and documented for preservation.

Of note on the nose, the registration number “DTR-916″ was primed prior to painting. As such, it was extremely durable and not removed by sanding. The “US AIR FORCE” marking on the other hand, was easily removed. We recommend these letters be reinstalled using durable vinyl lettering.

Progress was slow at this point. Daylight hours were short and sadly the flu struck at the same time, essentially stopping all meaningful work. This was the state of the aircraft when we were forced to retire till the opportunity presented itself to resume work.

So status: Some sanding remains on the aircraft and the left side still needs to be polished. For a uniform finish to accommodate for aging, we will probably quickly polish the right side again too.

Black areas on top of the nose and canopy need to be repainted. We recommend Air Force insignia and marking to be reproduced in vinyl lettering and graphics for the highest degree of quality.

Here is a surround video of the aircraft, taken in February of 2017

Part II August 2017

The schedule was cleared, redundancies put in place, and with a steely resolve to finish it this time, work began once again on the Cedar Rapids T-33.

Picking up where we left off, we started sanding the left side of the aircraft.

Applying what we learned were best practices from the last time around, we were able to sand much faster and complete most major sanding on the first day. To remove the sanding marks, we used a more aggressive cutting step. Although this produced a shiny surface, it also leaves behind holograms which will be refined with a more gentle finishing step.

Finishing polishing took a few days and was quite messy. After polishing was completed, it was time to start repainting. Essentially, this turned the T-33 in a giant model airplane!

The canopy and wingtip tanks were painted in a glossy black (with silver accents on canopy).

The designation of this T-33: DTR-916 was taped off and repainted as well.

The USAF insignia and Stars & Bars emblems were reproduced in vinyl and applied.

The vinyl insignia were the finishing touch on this Cedar Rapids landmark. It is with great pleasure that we concluded this restoration after countless hours of work.